Precision CNC Machining Services | Elite Craftsmanship

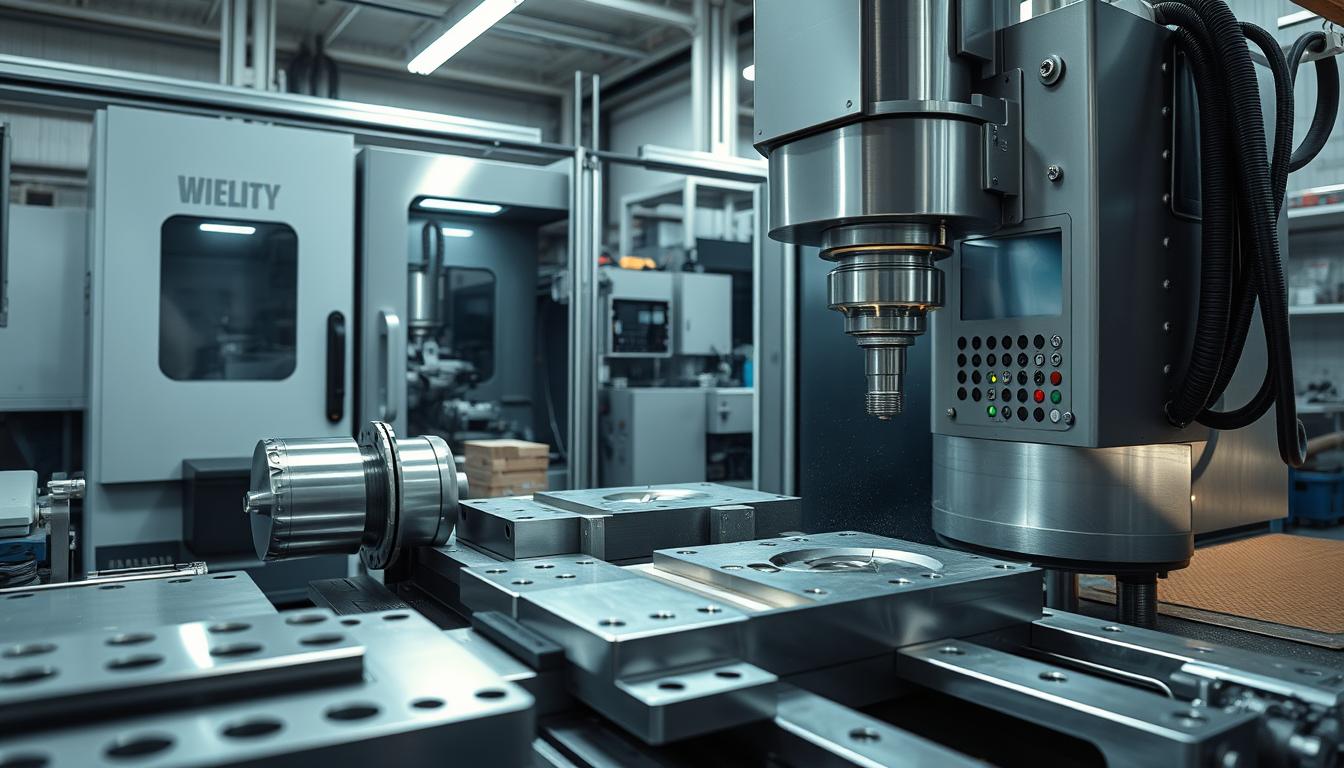

We blend art and engineering to offer top CNC machining services that meet your needs. Mekalite is known for its superior craftsmanship. We turn raw materials into detailed parts. Our cutting-edge tools and tech simplify complex tasks. This way, we make CNC components that precisely fit your demands and go beyond the usual standards.

Key Takeaways

- Our precision CNC machining services blend art and engineering seamlessly.

- Mekalite is synonymous with industry-leading CNC craftsmanship.

- We use state-of-the-art tools and technology to deliver high-precision CNC services.

- Our expert CNC machining solutions transform complexity into simplicity.

- We exceed industry standards with meticulous attention to detail.

Understanding Precision CNC Machining

Precision CNC machining is key in today’s manufacturing world. It uses computer controls to make parts very accurately. This advanced method changed how things are made, ensuring perfect parts every time.

What is CNC Machining?

The CNC machining process uses computer control for precise machinery operation. These machines follow detailed plans to cut and shape materials. By doing so, they create parts that match strict standards, improving production and cutting down errors.

The Importance of Precision in CNC

In precision engineering, being exact is everything. Precision CNC machining guarantees parts match strict quality checks. This is crucial in aerospace and medical fields, where small mistakes can lead to big problems.

Applications and Industries

CNC technology is used in many fields. It makes high-precision parts for cars and electronics. In aerospace, it ensures aircraft parts are safe. In medicine, it creates complex tools and implants for better patient care.

- Aerospace: Precision is key for safe flying.

- Medical Devices: High accuracy is needed for health care.

- Automotive: Parts need to meet tough standards.

- Electronics: High precision is crucial for these parts.

The table below shows the importance of precision in different industries:

| Industry | Key Requirement | Importance |

|---|---|---|

| Aerospace | Consistency in Tolerances | Critical for Safety |

| Medical Devices | High Precision | Essential for Patient Care |

| Automotive | Exact Specifications | Vital for Performance |

| Electronics | Component Accuracy | Necessary for Functionality |

Elite Craftsmanship in CNC Machining

We put our heart and soul into CNC machining. We’re all about top-notch quality and attention to detail. Our methods combine the latest techniques with a solid knowledge of materials. This mix ensures the best results every time.

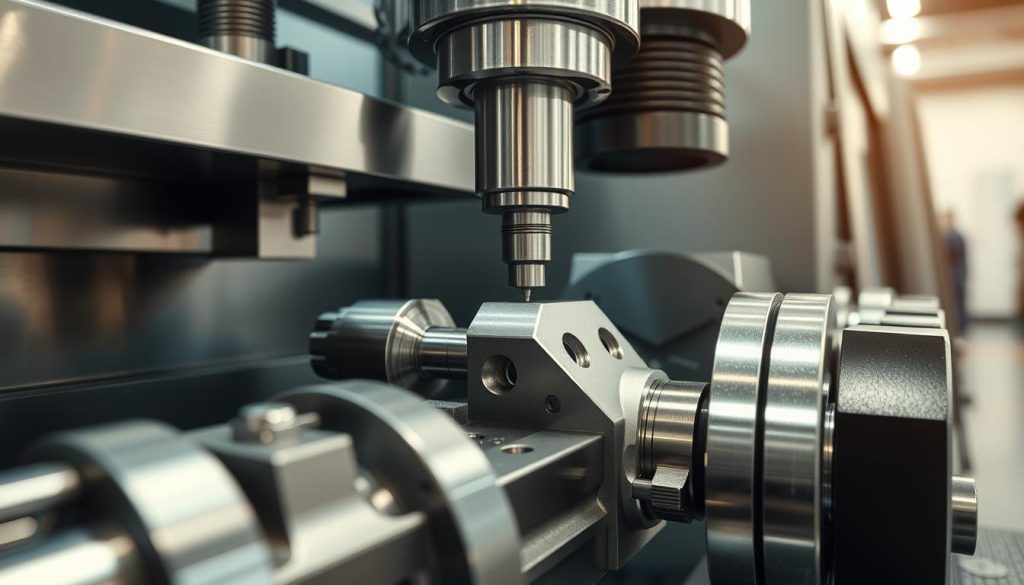

Our Approach to Precision

We find the perfect mix of tech skills and creativity. Our advanced CNC technology leads to unmatched precision. Every material is handled with care, making sure each action is spot-on.

Quality Assurance Methods

Quality is the base of what we do. We follow strict checks at each step. This makes sure everything we make meets the highest standards. When we promise quality, we mean it.

- In-depth inspections at every production stage

- Utilization of advanced metrology tools for precision measurements

- Consistency checks to maintain uniformity across batches

We take quality seriously. It’s at the core of our commitment to you.

Our Team of Experts

Our team is our pride. They have years of experience and a deep passion for their work. Their skills ensure we always deliver the best. Their drive for innovation keeps us ahead of the curve.

Technological Advances in CNC Machining Services

We’re at the forefront of the CNC machining industry, thanks to our commitment to innovation. By bringing in advanced CNC technology and cutting-edge machining software, we set new standards. We also explore new materials to achieve outstanding results for our clients.

Latest CNC Machinery

We’ve invested in the most modern CNC machines, known for their ultra-precise cuts and ability to shape complex figures. These machines come packed with the latest CNC technology. They help us tackle various challenging production demands with unparalleled precision, ensuring top quality in every product.

Software Enhancements

Our use of advanced CAD/CAM systems shows our dedication to innovation in machining software. These upgrades allow us to exceed traditional design limits, creating more complex and detailed patterns. This means we can turn any idea into a precise reality, seamlessly.

Material Innovations

We now work with a wider selection of materials, from classic metals to innovative composites. These new material options in CNC let us meet more specific and technical needs. It allows us to offer our customers improved performance features for their unique requirements.

| Technological Aspect | Impact |

|---|---|

| Advanced CNC Technology | Ultra-precise cuts and complex shapes |

| Innovative Machining Software | Enhanced design capabilities and customization |

| New Materials in CNC | Broader range of specialized and technical applications |

Benefits of Choosing Top-Tier CNC Machining Services

Working with the best CNC providers brings many benefits. These improve how things are made and the quality of what’s made. By choosing top-notch CNC machining services, clients receive advantages like:

- Enhanced part longevity: High-quality CNC components are precisely machined to meet exact specifications, leading to increased durability and performance.

- Greater material utilization: Advanced CNC techniques ensure minimal material wastage, optimizing resource usage and reducing costs.

- Thorough communication: Expert teams provide detailed insights and maintain clear communication channels throughout the project lifecycle.

- Customized solutions: Industry-leading CNC providers view each challenge as an opportunity for innovation, offering tailored solutions that meet specific client needs.

| Feature | Top-Tier CNC Machining | Standard Machining |

|---|---|---|

| Part Longevity | High, due to precision and superior materials | Moderate, with more frequent wear and tear |

| Material Utilization | Optimized, minimal waste | Less efficient, higher wastage |

| Communication | Thorough and clear | Inconsistent and unclear |

| Customization | Highly tailored solutions | Limited customization |

Choosing top-tier CNC services means getting innovative solutions and outstanding results. It guarantees reliability and excellence in every project.

CNC Machining for Custom Projects

Our advanced customization skills make sure your unique project needs are perfectly met. We’re proud of our ability to provide custom CNC solutions. These solutions meet a wide range of industry needs. This shows our dedication to top-notch quality.

Customization Capabilities

At the core of our offerings, project-specific CNC machining uses cutting-edge tech and expert skills to deliver custom results. Our capabilities include:

- Flexible design specifications

- Advanced prototyping methods

- Precision in complex geometries

- Material versatility

- High-repeatability production

We meet each project’s unique requirements, ensuring our solutions always surpass client expectations.

Case Studies

Our vast experience in CNC customization success stories covers many industries. We’ve taken on complex challenges with success. Below are some highlights:

- Aerospace Component Manufacturing: Created extremely precise components for top aerospace companies, improving durability and performance.

- Medical Device Prototyping: Made detailed prototypes for medical devices, meeting strict industry rules.

- Automotive Parts Fabrication: Manufactured unique auto parts, aiding in design and functional enhancements.

These examples show our deep expertise in crafting customized CNC solutions. These solutions are not just tailored to specific projects, but also pioneering in their field.

Materials Used in Precision CNC Machining

Choosing the right CNC machining materials is key for success in precision CNC machining. The material selected must meet high standards of strength, durability, and performance. Here are the top materials used because of their impressive qualities:

- Aluminum: Aluminum stands out for being light and easy to shape. It’s strong for its weight and fights off rust well. This makes it perfect for use in fields like aerospace, cars, and tech gadgets.

- Steel: Steel comes in varieties like stainless and carbon, known for toughness and strength. Its ability to handle heavy stress and high temperatures is vital for making industrial tools and machinery.

- Titanium: Titanium is famous for its strength, being light, and resisting rust well. Despite being hard to work with, its benefits are sought after in aerospace, medical, and high-end car parts.

- Specialty Alloys: Alloys like Inconel and Hastelloy are key for their ability to work under high temperatures and resist wear and rust. They’re crucial for specific fields like energy production and chemical processing.

Using these versatile materials in precision CNC boosts quality and possibilities for complex tasks. Each material offers unique benefits to meet the varied needs of different industries.

The Cost-Efficiency of Precision CNC Machining

Finding the right balance between cost and quality is key for companies wanting precision CNC machining. This first step assures smooth operations and leads to big savings later on. Let’s look at how this balance can give great benefits.

Cost vs. Quality

Many think high quality means high costs, leading to quick, not always best, choices. Yet, affordable CNC services can offer great quality and value. Spending on the best materials and latest techniques upfront cuts down on future fixes and makes products last longer.

Long-term Savings

Long-term CNC savings are important too. High-quality CNC investments mean less downtime, fewer mistakes, and parts that last longer. These all lead to big savings, letting companies use their money better.

| Cost Factor | Initial Investment | Long-term Savings |

|---|---|---|

| Material Quality | High | Significant |

| Skilled Labor | Moderate | High |

| Maintenance | Low | Substantial |

| Production Efficiency | Moderate | Significant |

Knowing the cost details of CNC machining helps leaders make smart, beneficial choices. Quality and efficiency in CNC tech investment mean success that lasts.

Partnering with Elite CNC Machining Providers

When you partner with us, you get top-notch CNC machining quality and innovation. We are a trusted CNC provider, focused on excellent results. Our goal is to achieve the highest customer satisfaction for your CNC machining needs.

Why Partner with Us?

Choosing us brings several advantages:

- Expert Technical Support: We have a team of experts with deep experience and knowledge.

- State-of-the-Art Machinery: Our latest CNC technology ensures precise and efficient work.

- Commitment to Quality: Strong quality control measures are in place to exceed your expectations.

- Customer-Centric Approach: Your satisfaction is our priority. We tailor our services to meet your needs.

Client Testimonials

See what our clients have to say about our work:

| Client | Feedback | Project Type |

|---|---|---|

| Boeing | “Their precision machining was flawless, and delivery was on time.” | Aerospace Components |

| General Electric | “Exceptional quality and reliable service every time.” | Industrial Equipment |

| Tesla | “Innovative solutions that pushed our project to new heights.” | Automotive Parts |

Future Trends in CNC Machining Services

The future of CNC technology is thrilling, full of promise. New trends are shaping the industry, making it better. We’re getting ready to provide even more precise and reliable services thanks to these developments.

Predictive Maintenance

Predictive maintenance is a big deal in CNC’s future. Advanced sensors and data help us spot problems before they happen. This means less downtime and better productivity. Our machines stay in top shape, making our CNC services better.

AI and Machine Learning

AI is changing CNC machining. Machine learning improves our work, making processes smarter. This leads to fewer mistakes and more efficiency.

Environmental Impact of Precision CNC Machining

We always check the environmental effect of our precision CNC machining. We stick to sustainable CNC practices. This makes sure every step is eco-friendly and saves energy.

Eco-friendly Materials

We choose materials for our machining that are good for the planet. These materials lower the environmental harm. They help cut down on waste and let us recycle and reuse materials.

Energy Efficiency

Our focus is on energy-saving CNC machining. We use modern machines that need less power but still work perfectly. We also use techniques that use energy wisely. This approach saves money and protects the environment.

By focusing on sustainability, we do better than what’s expected in the industry. This makes us leaders in green CNC manufacturing. And, we still give our customers the best service.

Conclusion

As we conclude, our precision CNC service commitment merges art and engineering beautifully. Each project, no matter its size, meets top standards of reliability and craftsmanship. We ensure that, every time.

Our role as a trusted machining partner spans various industries. We’re constantly embracing new technology while keeping strict quality checks. This dedication lets us explore new possibilities. Plus, our focus on sustainability highlights our drive in offering forward-thinking CNC solutions.

Our work goes beyond just supplying services; we’re about building success and fostering innovation. With our extensive offerings and focus on customers, we stand out for excellence in precision CNC machining. With us, you’re embarking on a journey of technological growth and sustainable practices, knowing you have a reliable partner with you.